ALUCORE®

We were the first tier 1 supplier and sawing company in Germany for ALUCORE® honeycomb composite panels from 3A Composites, and we are still the largest tier 1 supplier in Germany by far. That is why we are able to offer you the best price including cutting services.

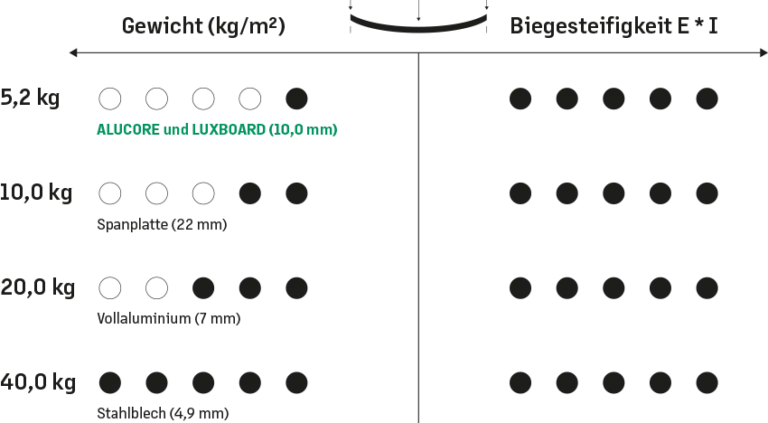

ALUCORE® stands out thanks to its unique combination of high flexural strength and low weight. These properties are what make ALUCORE® truly shine in terms of efficiency in structural applications compared to other products.

The honeycomb composite panels, which consist of two cover sheets and a honeycomb core made of aluminium, are produced from coil in large volumes using a continuous manufacturing process that involves viscoelastic bonding of the components. This process is the basis for achieving such high product quality, as the material does not become brittle-hard in response to bending loads.

Advantages of ALUCORE® composite panels:

High rigidity, high strength and flawless flatness

Low weight of between approx. 3.3 kg/m² and 7.3 kg/m²

Weight-bearing capacity and compressive strength

Simple processing and installation

Good corrosion resistance thanks to the use of high-quality aluminium alloys

Painted in platinum white (similar to RAL 9003)

Individual surface finish; surface is suitable for screen printing

Sound reduction index: between 21 and 25 dB

Heat transfer coefficient: approx. 5.58 to 5.67 W/m²K

Fire protection class B1 (low combustibility)

All required certifications according to IMO/SOLAS (or also: MED, Wheelmark, EC type examination certificate) US Coast Guard

Cut-to-size panels and CNC-machined, finished parts – supplied to you

100% recyclable thanks to the use of aluminium for both the core and the cover sheets

Available from stock at short notice

We produce ALUCORE® panels at a length of up to 9 m and keep lengths of up to 6.25 m in stock.

The panels are generally available directly from stock within 1 to 2 weeks. Do you need the panels urgently? Then don’t hesitate to get in touch with us.

Thicknesses: 5,5 mm, 6 mm, 10 mm, 15 mm, 20 mm, 25 mm

Widths: 1250 mm, 1500 mm

Lengths: 2050 mm, 2500 mm, 3050 mm, 4050 mm, 5050 mm, 6250 mm

Cover sheet thickness: between 0.5 mm and 1.0 mm depending on panel thickness

Surface finish: platinum white on both sides (similar to RAL 9003), stove-lacquered

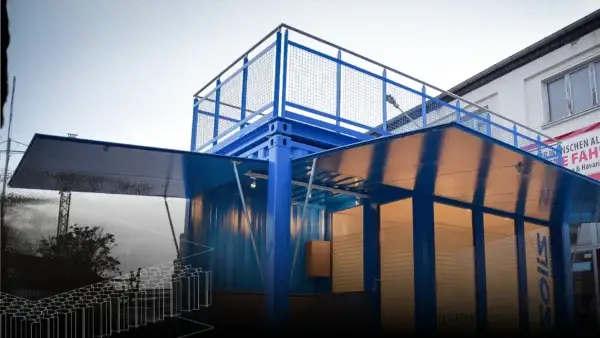

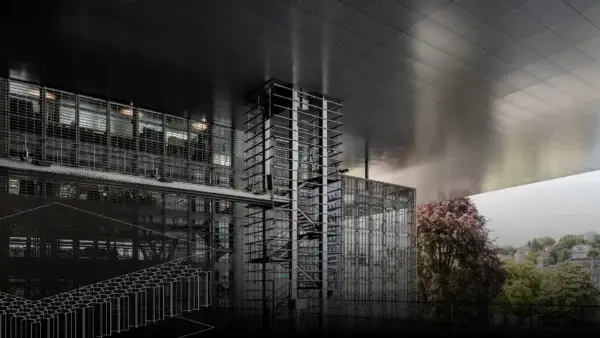

ALUCORE® References

Exciting projects and case studies from our customers that have been implemented with ALUCORE®.

ALUCORE® machining

We cut the panels to size according to your preferences in our machining centre in Düsseldorf.

We perform cutting and milling operations on modern 5-axis CNC machines and panel saws – including sawing, milling, drilling and surface coating.

Our range of services also includes shaping the panels using bending and folding techniques, implementing a range of fixing systems and applying various finishes, including lacquer finishes and self-adhesive films.

Custom designs

If you are interested in custom designs of our aluminium honeycomb composite panels, then don’t hesitate to get in touch with us. We can usually implement specific requirements and dimensions according to your specifications.

Applications

for ALUCORE®

The honeycomb composite panels from 3A Composites are incredibly versatile and are used in a wide range of applications: ALUCORE® is highly valued in the vehicle construction industry due to its low weight and stability. But that’s not all – ALUCORE® is also perfect for use in interior design applications for creating functional ceilings and partition walls, for example. Furthermore, ALUCORE® has properties that make it ideally suited for use as a reinforcement for floor structures or load-bearing panels when robust and long-lasting solutions are needed. Thanks to its wide range of applications, ALUCORE® is a preferred material in areas that require a combination of low weight and excellent durability.

Whether in shipbuilding, building and construction or railway vehicle construction: ALUCORE® has the relevant approvals and certifications for all of these areas, which you can view here:

Calibration plates

ALUCORE® is perfect for large-scale applications such as calibration plates. Conventional materials are often unable to meet the requirements of calibration plates due to their weight and an insufficient degree of flatness. We have closed this gap with our

Outdoor applications

ALUCORE® honeycomb composite panels are suitable for outdoor applications. They are weather resistant and durable. When used in outdoor applications, the cut edge of the panel must be protected against atmospheric conditions. We recommend using our:

Download

You can find further information, documents and certificates in the Download area.

Approvals

Shipbuilding

| MED approval (EC Type Examination Certificate, Wheel Mark) US Coast Guard Type Approval | EU US | Modules B and D Surface materials and floor coverings with low flame-spread characteristics (decorative veneers and floor coverings) |

| MED approval (EC Type Examination Certificate, Wheel Mark) US Coast Guard Type Approval | EU US | Modules B and D Fire-restricting materials for high-speed craft |

| DNV GL rules for classification – Ships DNV GL offshore standards DNV GL – SI – 0364 – SOLAS | EU US | Class C Division Certificate TAF0000K8 |

Railway vehicles

| DIN 5510 | Germany | S5 / SR2 / ST2 |

| EN 45545 | EU | HL3 (for R1) |

| NF F 16-101 | France | Class F0 |

| NF P 92-501 | France | Class M1 |

Construction

| DIN 4102 | Germany | Class B1 flame-retardant |

| DS 1065.1 | Denmark, Norway, Sweden | Class A |

| NF P 92-501 | France | Class M1 |

| NF F 16-101 | France | Class F0 |

| VKF Fire Safety Guidelines | Switzerland | Class 5.3 |

| BS 476, Part 6 | United Kingdom | Index 0 |

| BS 476, Part 7 | United Kingdom | Class 1 Class 0 according to UK Building Regulations |

| DIN EN 13501-1 | Germany | A2 |

Your contact persons

Our composites experts will guide you through the planning and implementation of your project. We’re here for you!