LUXBOARD

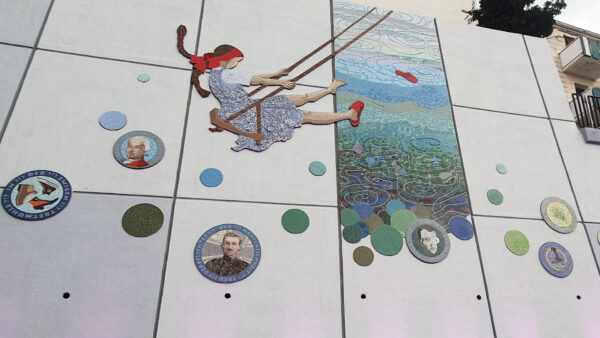

Very high flexural rigidity, low weight and simple processing: These properties make LUXBOARD aluminium honeycomb composite panels incredibly versatile.

LUXBOARD differs from our premium segment its surface is simply finished with a primer. This makes it simple to carry out a wide range of further processing options and enables the panels to be sold at an affordable price.

Due to the use of aluminium for both the core and the cover sheets, these aluminium honeycomb composite panels are 100% recyclable.

Vorteile von LUXBOARD Wabenverbundplatten:

Extremely low weight: only 4.7 kg/m² at a thickness of 6 mm

Excellent flexural rigidity

Sound reduction index: up to 25 dB

Fire protection classification A2-s1: non-combustible

High moisture resistance

High corrosion resistance

Excellent thermal conductivity

Temperature resistant to 110 °C

High peel strength, tensile strength and shear strength

Environmentally friendly: 100% recyclable and chrome-free

Available from stock at short notice

Thicknesses: 4 mm, 6 mm, 8 mm, 10 mm, 12 mm, 15 mm, 20 mm, 25 mm, 30 mm, 34 mm (other thicknesses available upon request)

Lengths: 2050 mm, 2500 mm, 3050 mm, 4050 mm, 5050 mm, 6250 mm

Cover sheet thickness: Front and rear sheet 1.0 and/or 0.5 mm; other thicknesses are available upon request

Nominal cell width: approx. 9.4 mm

Surface finish: primer

LUXBOARD processing

In unserem Düsseldorfer Bearbeitungszentrum sägen wir die LUXBOARD Platten nach Ihren Anforderungen zu.

We perform cutting and milling operations on modern 5-axis CNC machines and panel saws – including sawing, milling, drilling and surface coating.

Our range of services also includes shaping the panels using bending and folding techniques, implementing a range of fixing systems and applying various finishes, including lacquer finishes and self-adhesive films.

Download

You can find further information, documents and certificates in the Download area.

Your contact persons

Our composites experts will guide you through the planning and implementation of your project. We’re here for you!