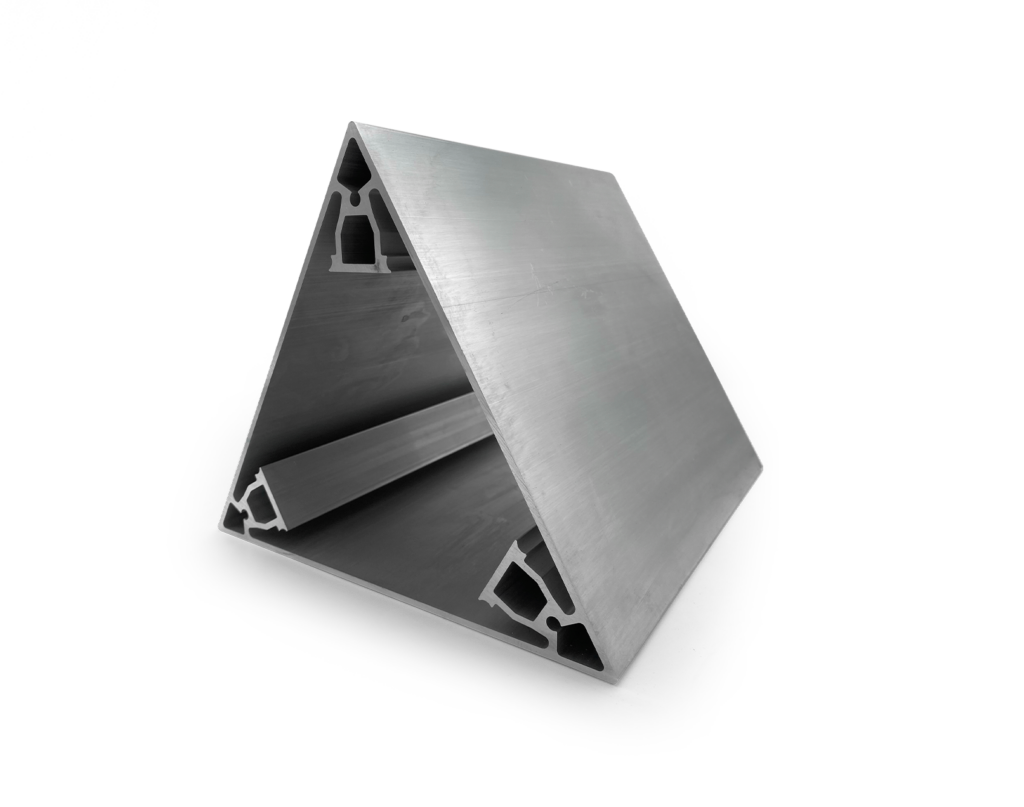

Custom profiles

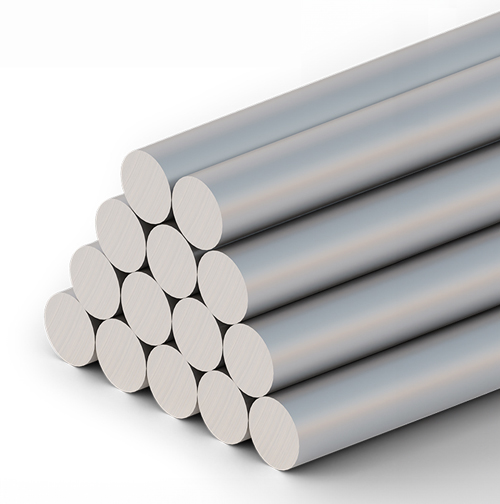

Custom aluminium profiles according to your specifications

Do you need custom-made profiles rather than a standard solution for your project? We will guide you through the entire process – from the drawing right through to the delivery of your custom profiles. Our production network includes a comprehensive range of presses, and this means that we will find the right press for any profile, no matter how big or small it is.

Your advantages at a glance:

Personal advice

Over 30 extrusion presses

Compressive forces of between 400 and 8,000 tonnes

In-house foundry

In-house tool and die shop

Reliable delivery dates thanks to optional storage in Germany

In-house anodising and powder-coating plants

Machining

Minimum orders starting from approx. 500 kg

mejo Metall Josten specialises in special aluminium profiles and custom aluminium profiles. This has been our area of expertise since 1932 and is by far our largest business segment. We support our SME customers throughout the entire process – from the original concept to the extruded aluminium profile and through to the further processing and surface finishing stage.

We find the right extrusion press for your profile and guide you through the entire process transparently.

Interested?

You can arrange a no-obligation discussion to see how we can help you:

Range of services

We are 80 independent aluminium profile specialists. Delivering and manufacturing custom aluminium profiles and special aluminium profiles for SME customers from the industrial sector is what we do every day.

Thanks to our selection of extrusion presses, our long-standing partner plant contacts and, most importantly, volume consolidation, aluminium profiles and global purchasing are now a viable option for many SMEs for the first time. We know the requirements and processes of our partner plants, and we have the necessary volumes to get their attention and discuss projects on an equal footing. Our warehousing facilities in Germany guarantee efficient planning, consistent quality and reliable delivery dates. This saves time and prevents frustration.

You can read about the entire process – from consultation to delivery – in our blog post on this topic.

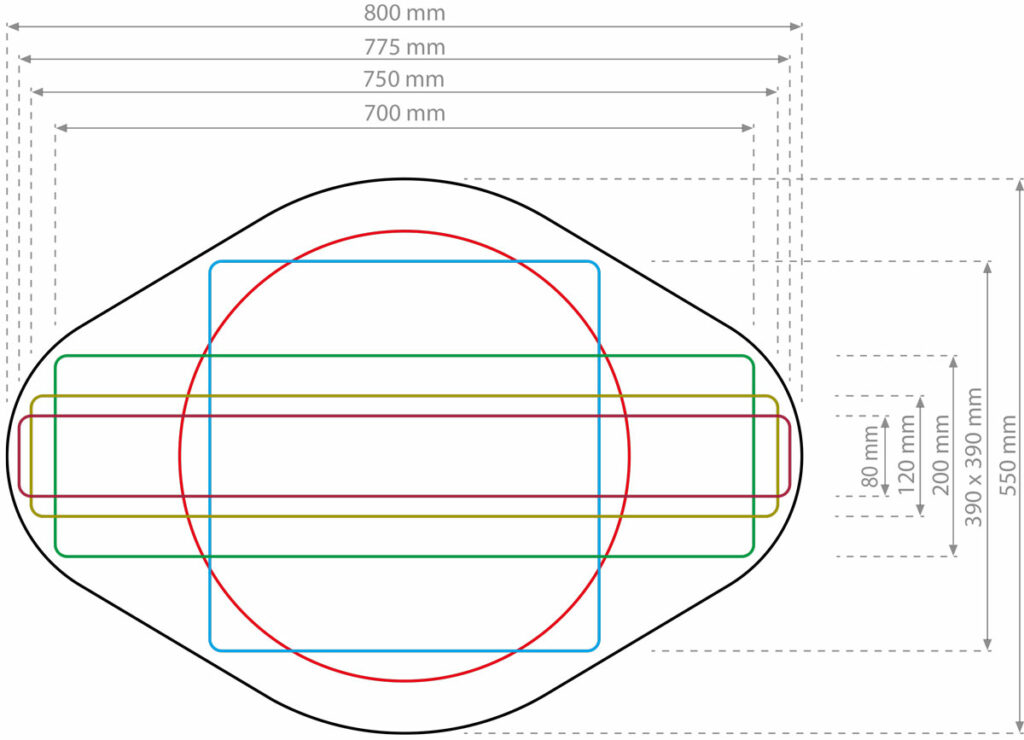

Specifications and services for custom profiles:

On our six melting furnace lines, we can implement specific requirements regarding the visual appearance or mechanical properties of your custom profile. We produce 6000 series aluminium alloys on these lines and can influence certain alloy constituents in accordance with your specifications.

| EN AW-6060 |

| EN AW-6061 |

| EN AW-6063 |

| EN AW-6005 |

| EN AW-6005A |

| EN AW-6082 |

Is sustainability an important issue for you?

We offer you the opportunity to reduce your carbon footprint during the production of billets. You can find out more about this under Sustainability at mejo or you can simply ask us directly.

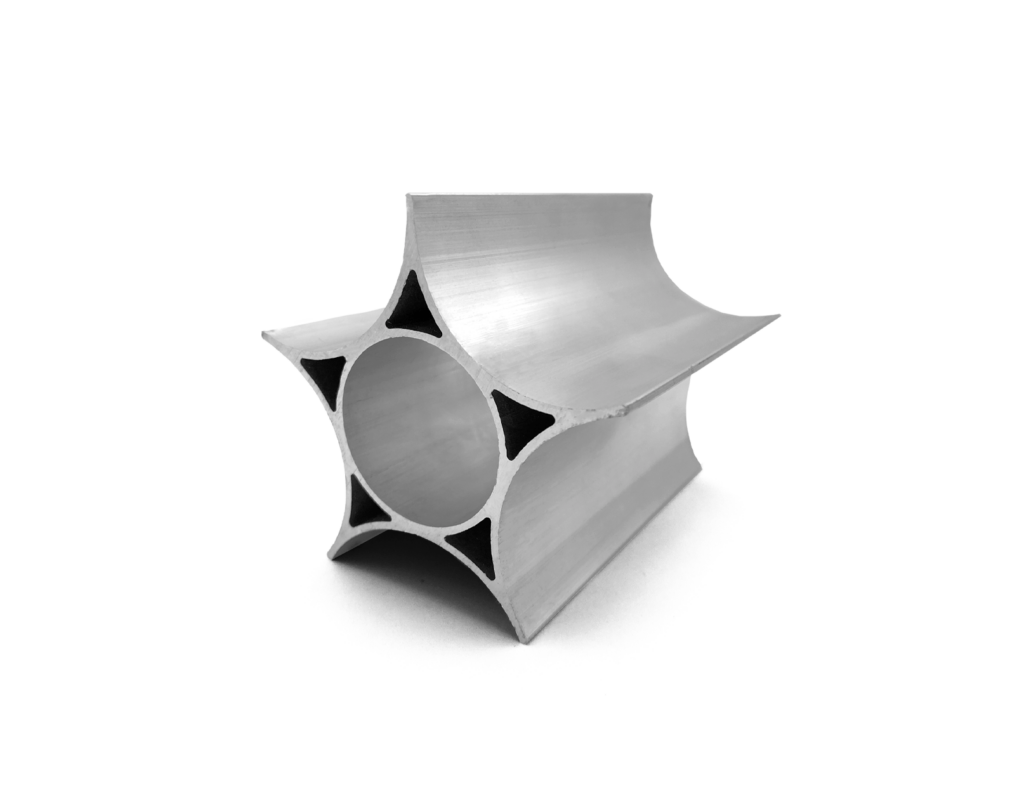

We are happy to print your custom profile based on the CAD drawing as a high-quality, 3D-printed sample made of plastic using our in-house 3D printer. With a production time of approximately one working day, you will have your sample profile in your hands in no time. If modifications still need to be made to the die, then we can discuss these with you before the die making process begins.

The die making process is a crucial factor for the quality and cost-effectiveness of the delivered profiles. A good die is essential to meet the required quality standards and achieve the required level of stability.

That’s why we make the majority of the dies we need for our production in our own tool and die shop. However, in exceptional cases, we also purchase dies produced by renowned companies according to precise specifications. Apart from a few exceptions, corrections and adjustments are always carried out in our in-house tool and die shop.

For batch sizes of 5 tonnes and above, the production of most dies is free of charge for our customers.

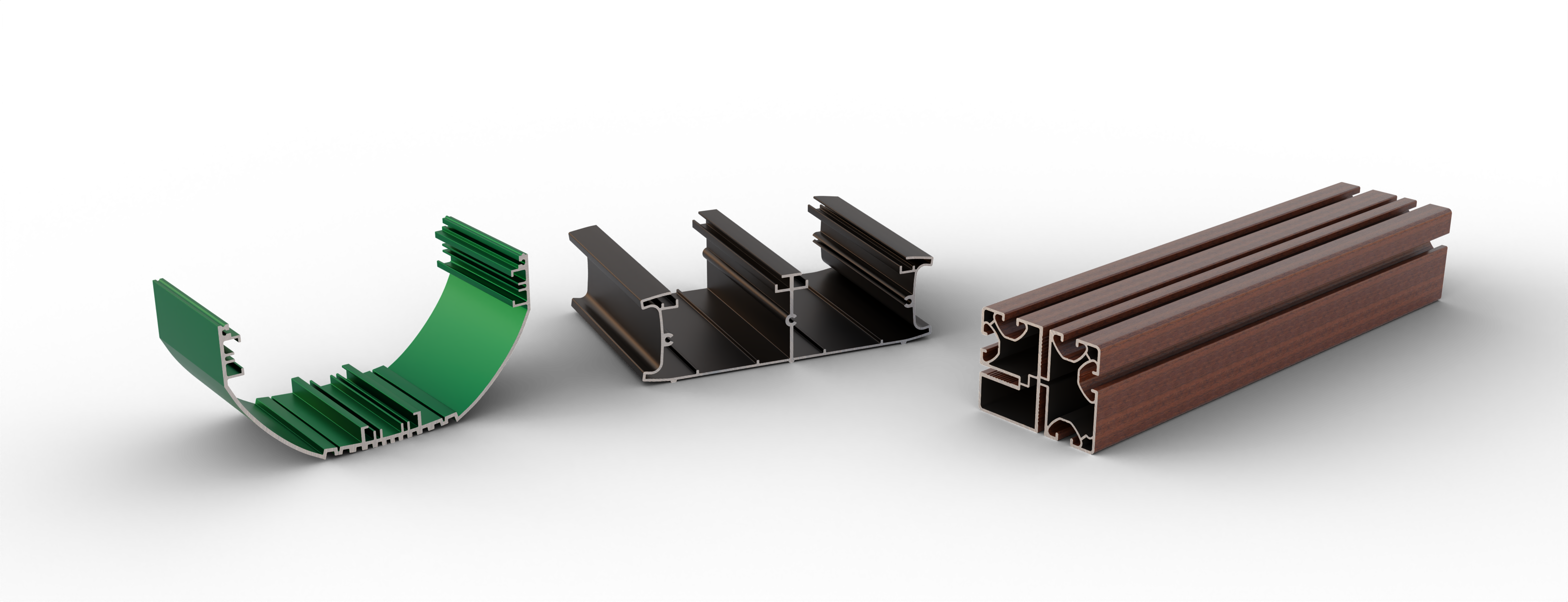

A surface treatment gives your profile that extra something and takes it to the next level. Furthermore, surface treatments do more than just create an attractive visual appearance. Surface treatments also provide protection for a wide range of applications and mean that your profile is ready to use as soon as it is delivered.

We offer you the choice of a powder-coated finish, an anodised finish or a wood-effect coating.

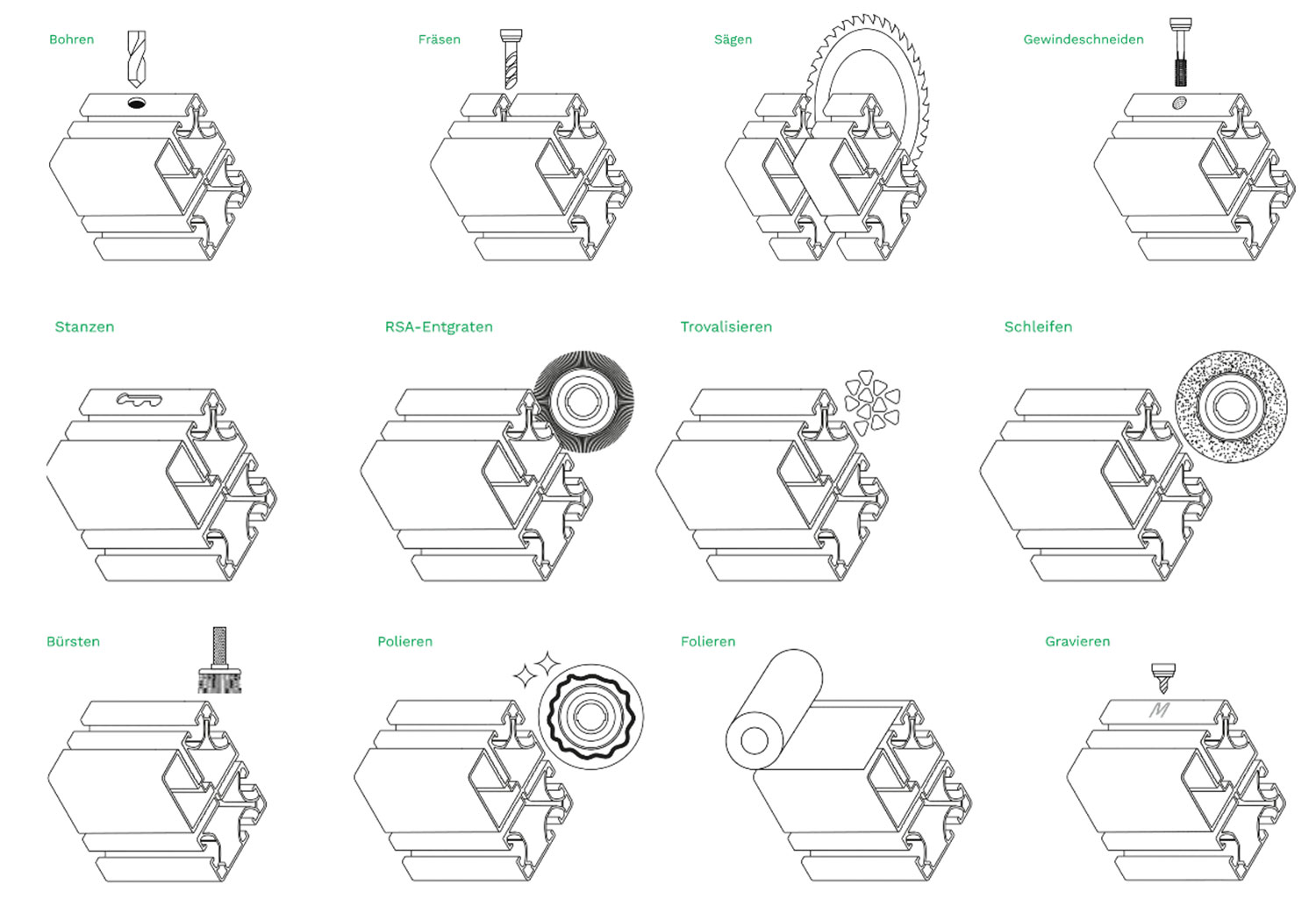

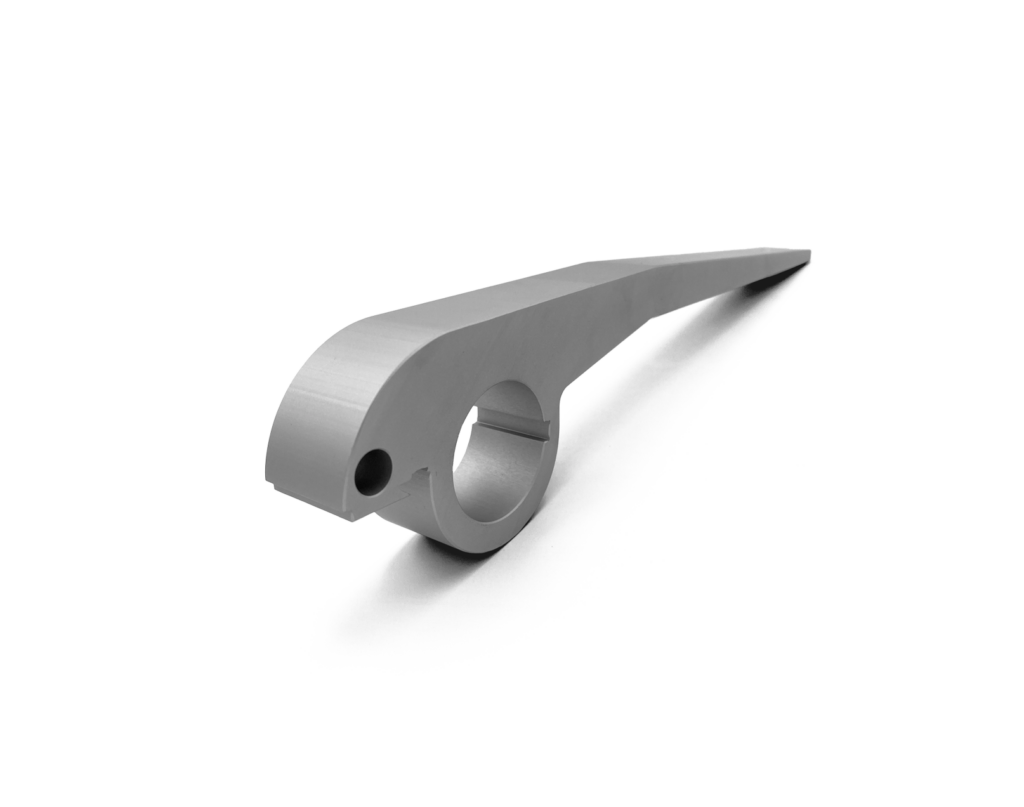

We carry out the required machining work on automatic saws, CNC rod machining centres and vibratory finishing machines. We offer the following machining options for your special profiles and custom profiles:

Sustainability and environmental protection are issues that affect us all. They play an important role in our everyday lives. Thankfully, aluminium can be repeatedly recycled. Aluminium is very durable and can be fed back into the material cycle an infinite number of times. That is why we also offer an environmentally friendly recycling service for our larger customers and system partners. We then credit the relevant amount to your account following receipt of the scrap aluminium.

You can find more information about our range of services here.

Download

Information leaflet: Custom profiles

You can find further information, documents and certificates in the Download area.

Standard profiles

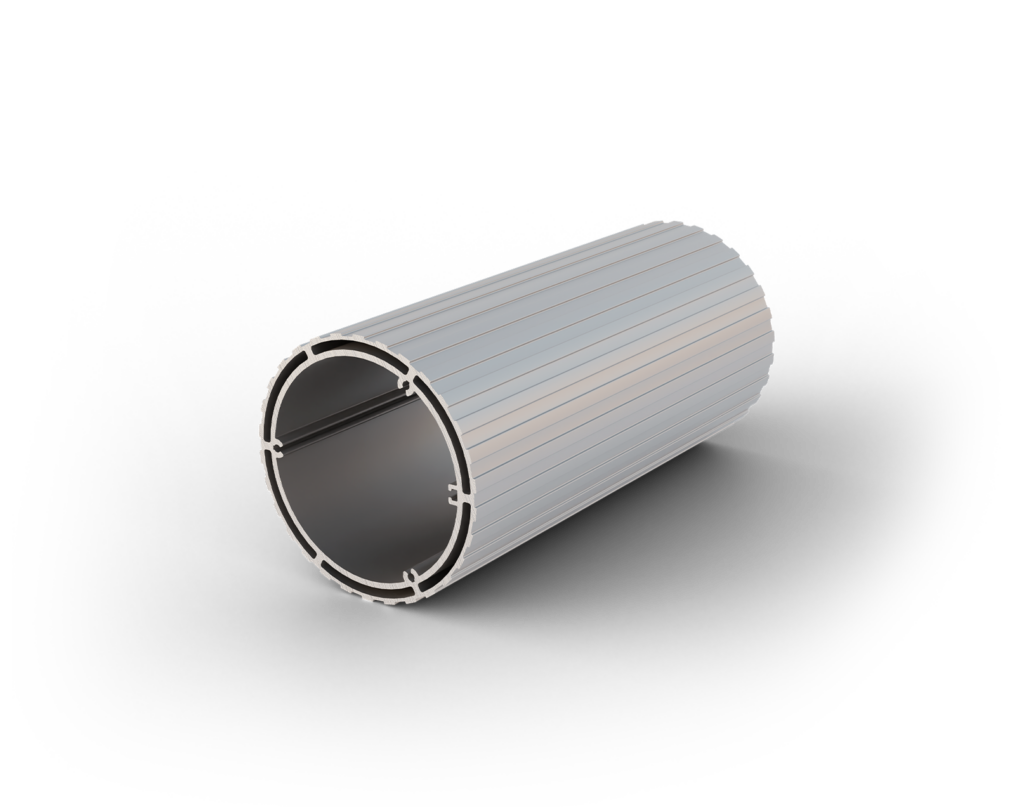

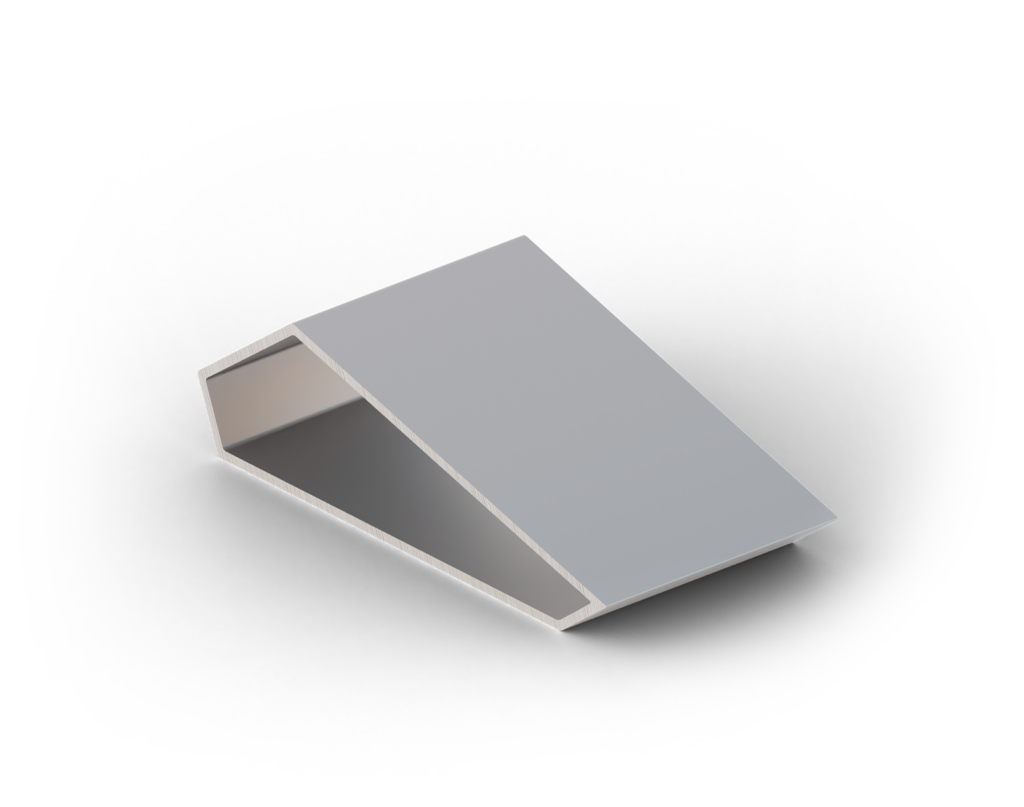

In addition to special profiles and custom profiles, we also offer standard profiles. The dies used to produce these profiles are freely available.

Can’t see the right geometry for your project?

Additional geometries are available upon request.

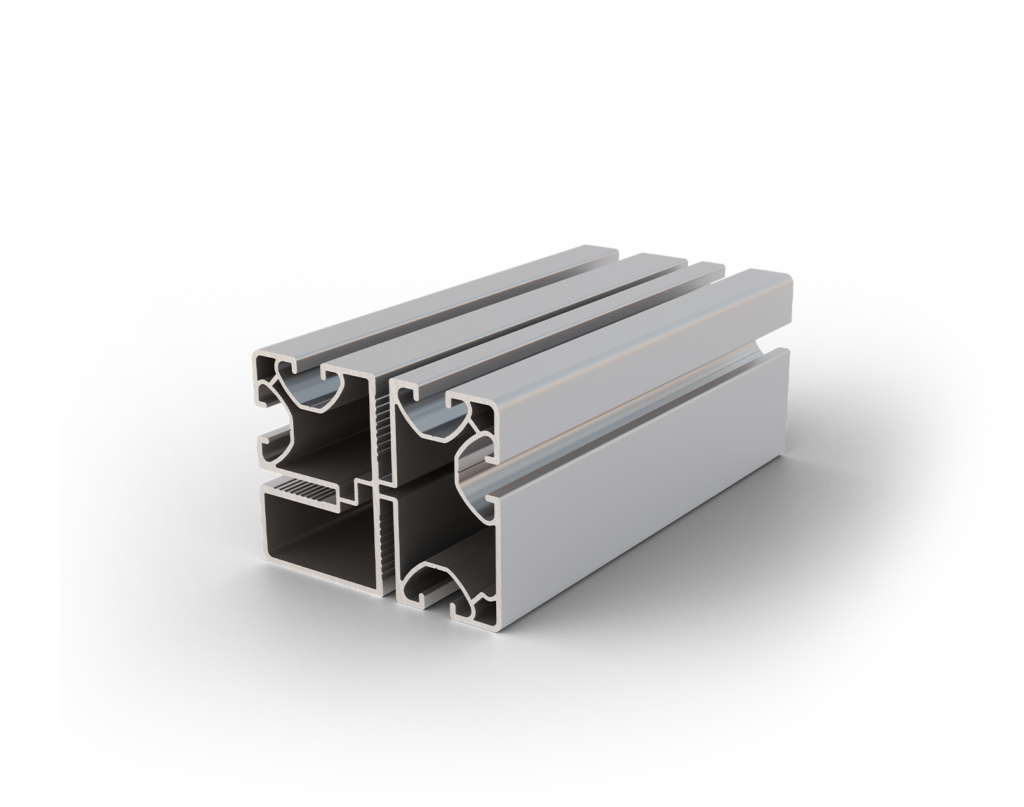

References

Our profiles are used in a wide range of industries: including the electrical industry, construction, interior design, medical technology, cooling technology, drive technology and many more. Not every profile is suitable for every press. Finding the right press and also making difficult geometries possible can be tricky – but this is where our many years of experience in the extrusion of aluminium comes into play.

See for yourself.

Light technology

- Special feature: chambers

Protective grating systems for the automotive industry

- Special feature: tongue ratio

Battery holder

- Special feature: high coolness factor

LIGHT TECHNOLOGY

- Special feature: chambers

REHAB TECHNOLOGY

- Special feature: distribution of mass

AUDI CITY PARIS

- Special feature: straightness and torsion

FAQ

We have answered the most frequently asked

questions here:

Your contact persons for custom profiles

Our experts in special and custom profiles will guide you through the planning and implementation of your project. From the initial concept to the delivery of your finished profile: We’re here for you!